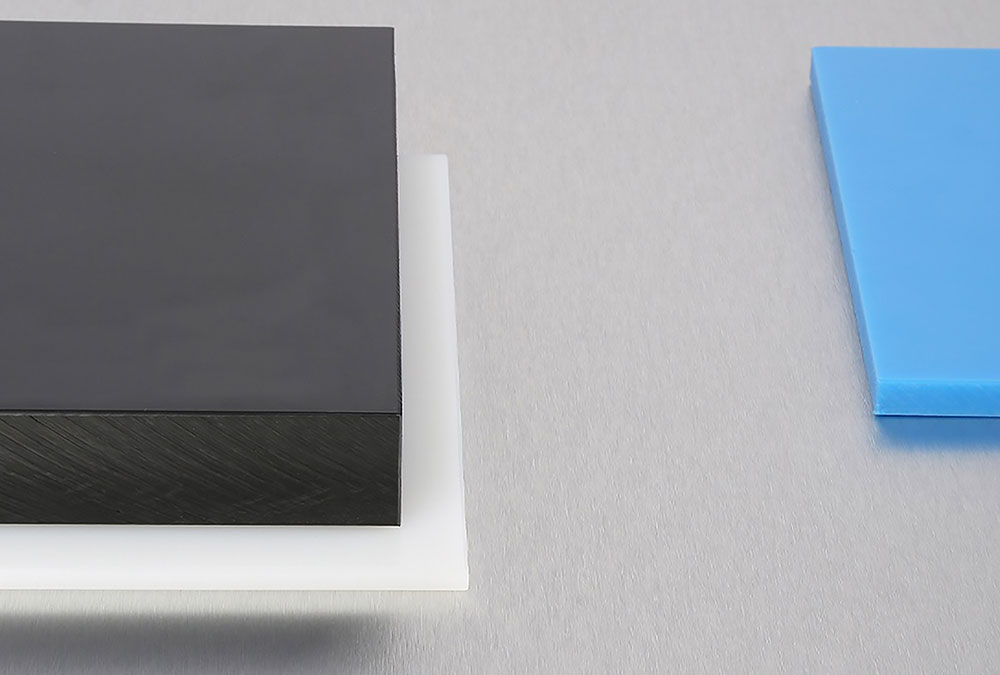

Polyethylene (PE)

-

PE-LD (Low-Density Polyethylene)

-

PE-HD (High-Density Polyethylene)

-

UHMW-PE (Ultra High Molecular Weight Polyethylene)

PE-LD (Low-Density Polyethylene)

PE-LD is a highly flexible plastic known for its excellent impact strength and electrical properties. It is widely used in façade systems that require flexibility and shock absorption.

Key Properties:

Temperature Range

Flexibility & Impact Strength

Moisture Absorption

Food Contact

-50°C to +80°C.

High flexibility and excellent shock absorption.

0.1%.

Approved.

Available Forms: Sheets

Façade Applications:

- Flexible cladding systems.

- Protective linings for packaging and processing zones.

PE-HD (High-Density Polyethylene)

High-Density Polyethylene is a tough, lightweight plastic with excellent chemical resistance and low moisture absorption. It is categorized into two main grades:

- PE-HD (300): A robust, lightweight plastic with excellent sliding and impact properties. Its corrosion resistance and hygienic qualities make it ideal for food processing zones and automotive/leisure façades.

- Available Forms: Sheet, Rod, Angle, Hollow Rod, Channel, Square Tube, Weld Rod.

- PE-HD (100): A certified grade engineered for high-pressure environments. It offers superior resistance to stress cracking, making it ideal for structural and containment applications.

- Available Forms: Sheet, Pressure Pipe, Weld Rod.

Shared Properties:

Temperature Range

Impact Strength

Chemical Resistance

Moisture Absorption

Food Contact

-50°C to +80°C.

High.

Excellent.

0.1%.

Approved.

Façade Applications:

- Internal wall cladding for hygienic zones.

- Ventilation systems and ducts.

- Handling tanks and pump bodies.

- Containment for corrosive fluids.

UHMW-PE (Ultra High Molecular Weight Polyethylene)

UHMW-PE represents a range of premium-grade polyethylenes engineered for high-performance applications.

PE 500

PE 500 Confetti (Reprocessed)

PE 1000:

PE 1000-R (Reprocessed)

PE 1000-EL (Electrically Conductive):

PE 1000-MD (Metal Detectable)

PE UltraPlus®

A food-grade polyethylene with excellent impact strength and abrasion resistance. Its low friction coefficient and wear properties are suitable for high-impact zones and hygienic environments. Temperature Range: -60°C to +80°C.

A cost-effective, multi-colored alternative to virgin PE 500. Ideal for non-critical façade applications where corrosion and impact resistance are required without food compliance. Temperature Range: -50°C to +80°C.

A premium-grade offering exceptional abrasion resistance, sliding properties, and toughness. Food compliant and ideal for high-performance systems. Temperature Range: -200°C to +80°C.

A recycled alternative to virgin PE 1000. It retains core mechanical properties but is not for food contact. Temperature Range: -100°C to +80°C.

Permanently antistatic and conductive, making it ideal for electrically sensitive or explosive hazard areas.

Designed for metal detection in food and packaging environments.

Features built-in dry lubricants for ultra-low friction and noise absorption. Engineered for conveyor systems and high-wear zones.

All UHMW-PE Grades:

- Moisture Absorption: <0.1%

- Available Forms: Sheet, Rod, Wearstrip (varies by grade).