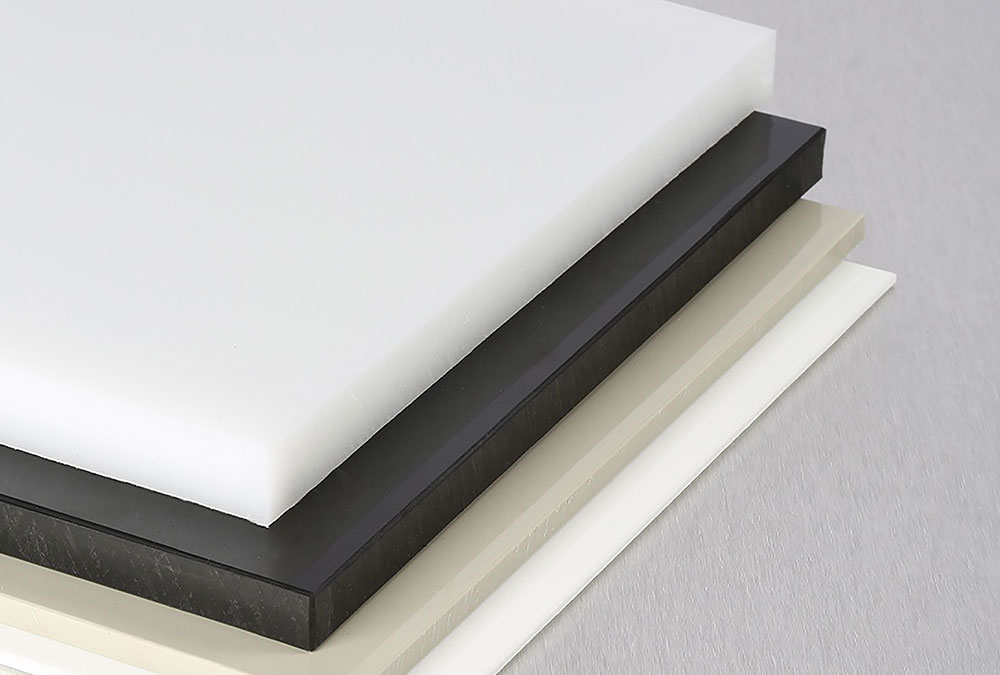

Polypropylene (PP)

- PPC (Polypropylene Copolymer)

- PPH (Polypropylene Homopolymer)

- PP-FR (Polypropylene – Fire Retardant)

- PPC-PB (Polypropylene Copolymer – Polyester Backed)

- PP/PE-R (Polypropylene/Polyethylene – Regenerated)

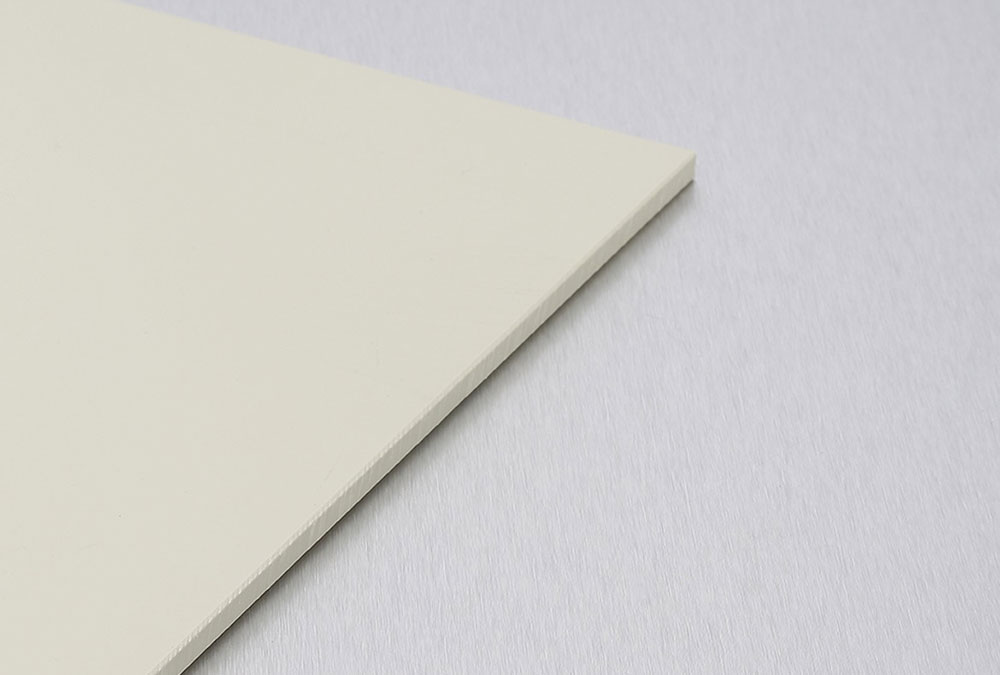

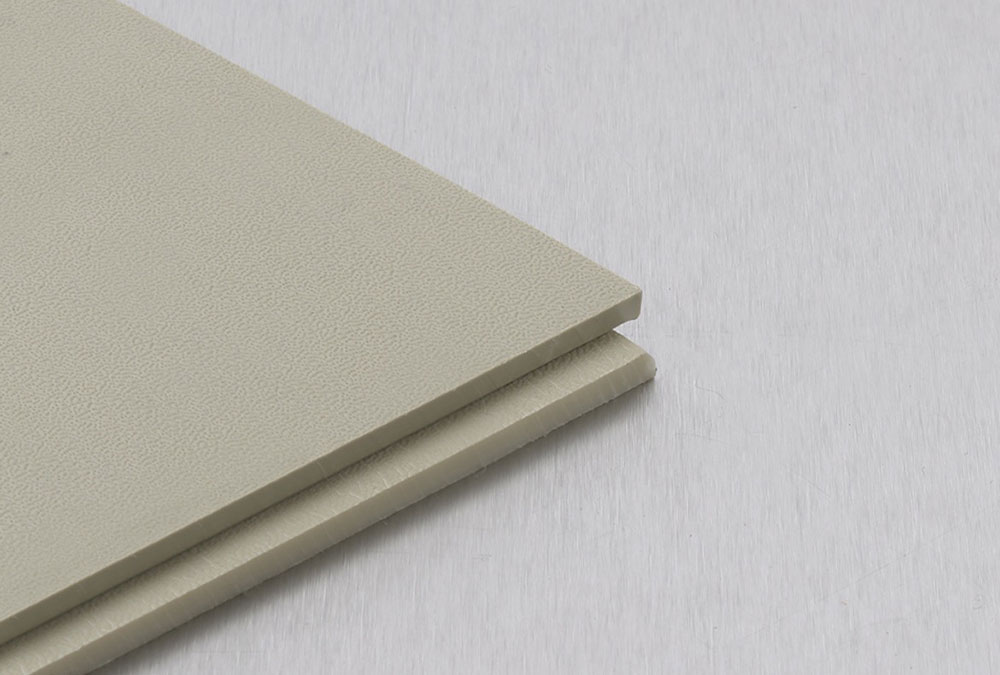

PPC (Polypropylene Copolymer)

PPC is a lightweight, impact-resistant plastic with excellent chemical stability. Its weldability and low moisture absorption make it suitable for both structural and decorative façade elements.

Key Properties:

Available Forms:Sheet, Square Tube, Weld Rod.

Façade Applications:

- Protective cladding.

- Chemical tanks and containment.

- Signage and advertising panels.

PPH (Polypropylene Homopolymer)

PPH offers superior rigidity and thermal stability. It is ideal for high-temperature façade systems, though it may become brittle in low-temperature environments.

Key Properties:

Available Forms: Sheet, Rod, Angle, Square Tube, Hollow Rod, Pressure Pipe, Channel, Weld Rod.

Façade Applications:

- Components for high-temperature zones.

- Cutting boards and gaskets.

- Pumps and valve bodies.

PP-FR (Polypropylene – Fire Retardant)

PP-FR retains the core benefits of standard polypropylene with added fire resistance. This makes it a perfect material for HVAC and façade ventilation systems.

Key Properties:

Available Forms: Sheet, Weld Rod.

Façade Applications:

- Components for high-temperature zones.

- Cutting boards and gaskets.

- Pumps and valve bodies.

PPC-PB (Polypropylene Copolymer – Polyester Backed)

PPC-PB is reinforced with a polyester backing, which allows for fiberglass integration, giving it metal-like strength. It’s ideal for manufacturing large-scale façade tanks and structural panels.

Key Properties:

Available Forms: Sheet.

Façade Applications:

- Large structural tanks.

- Reinforced façade panels.

PP/PE-R (Polypropylene/Polyethylene – Regenerated)

PP/PE-R is a cost-effective blend of regenerated PP and PE. While it is not recommended for critical welding, it is suitable for non-structural façade elements and general use where a low-cost, durable material is needed.

Key Properties:

Available Forms: Sheet.

Façade Applications:

- Signage and linings.

- Impact strips and non-critical cladding.