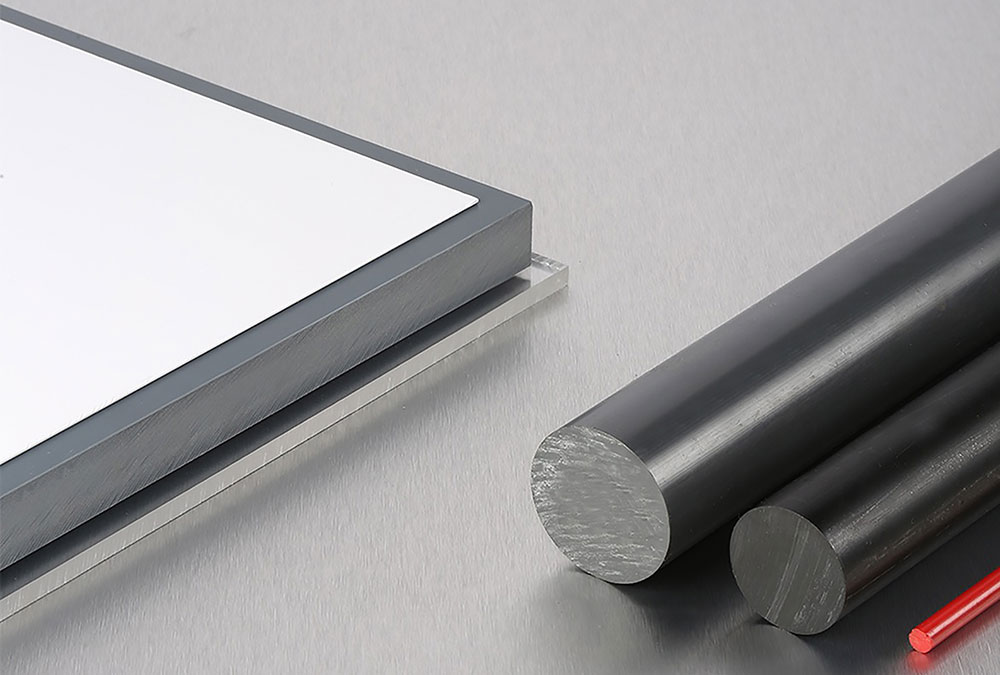

PVC (Polyvinyl Chloride)

- Solid Rigid Sheets (PVC)

- uPVC (Unplasticised Polyvinyl Chloride)

- CPVC (Chlorinated Polyvinyl Chloride)

- uPVC Cladding & Foam

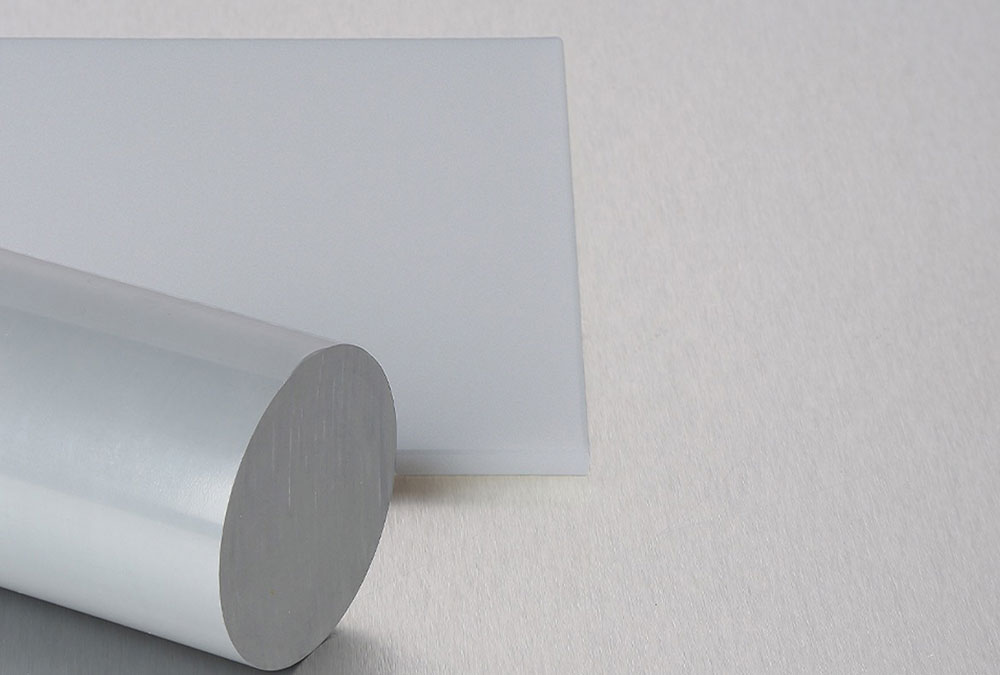

Solid Rigid Sheets (PVC)

Solid PVC is a highly reliable and chemically resistant plastic. Its self-extinguishing and electrically insulating properties make it an ideal material for industrial and construction applications. It is commonly used for creating durable electrical enclosures, insulation panels, and filler strips in façade systems.

Key Features & Technical Aspects:

Façade Applications:

- Electrical enclosures and panels.

- Filler strips and seals in construction.

- Durable cladding for industrial areas.

uPVC (Unplasticised Polyvinyl Chloride)

uPVC is a rigid, high-performance plastic that offers exceptional chemical resistance and tensile strength. Its inherent dimensional stability and weldability make it an optimal choice for demanding industrial and façade applications where durability and structural integrity are paramount. It holds a Class 1 fire rating.

Key Features & Technical Aspects:

Façade Applications:

- Internal wall cladding for hygienic zones.

- Ventilation systems and ducts.

- Handling tanks and pump bodies.

- Containment for corrosive fluids.

CPVC (Chlorinated Polyvinyl Chloride)

CPVC offers enhanced thermal resistance and rigidity compared to uPVC. This material is designed to maintain its structural integrity at higher temperatures, making it a superior choice for chemical and pharmaceutical environments where elevated temperatures are a factor.

Key Features & Technical Aspects:

Façade Applications:

- Cladding in chemical processing zones.

- Pharmaceutical containment and enclosures.

uPVC Cladding & Foam

- uPVC Cladding: A fire-rated and food-approved solution that creates hygienic, durable, and easy-to-maintain environments. Its chemical resistance and ease of fabrication are ideal for sanitary and high-traffic architectural zones.

- Available Forms: Sheet, Profiles, Adhesive, Silicone, Rivets.

- Decorative uPVC Cladding: Combines hygienic performance with aesthetic appeal. Features ten high-resolution, digitally printed wall designs protected by a UV-cured clear coating for enhanced durability and chemical resistance.

- uPVC Foam: A lightweight, fire-rated material with low thermal and sound conductivity. Its smooth surface makes it perfect for printing, signage, and decorative façade elements.

- uPVC Co-extruded Foam (Coplast): Features solid outer surfaces for enhanced durability and impact resistance. It provides improved thermal and chemical performance, making it an excellent choice for cladding and partitions.